RC Hobby Parts

RC Hobby Parts

Founded in 1979 in Taiwan, we build metal components for RC programs with clear process planning, tooling engineering, and measurable production controls. For thin‑wall cups, housings, and cylindrical shapes, our deep draw forming workflow manages draw ratio, blank holder force, lubrication, and multi‑stage operations to keep geometry and wall‑thickness within target.

Process Capabilities

We combine blanking, piercing, bending, coining, and secondary machining with deep draw metal forming when parts call for higher draw depth. The route can include trimming, flanging, re‑draw, calibration, and annealing to prevent wrinkling, thinning, or tearing, and to stabilize fit across production lots.

Tooling Engineering

Dies are developed with 2D/3D reviews, spring‑back checks, radii and clearance control, wear tracking, and bead placement. Try‑out iterations tune pressure settings and strip layouts. First Article Inspection (FAI) records baseline data and locks parameters for consistent output.

Quality Control

Incoming checks, in‑process inspection, and final verification follow part risk. Key items: concentricity, thickness scan, dimensional tolerance, surface evaluation, and leak tests when needed. Batch records and traceability marks support audits and supplier management.

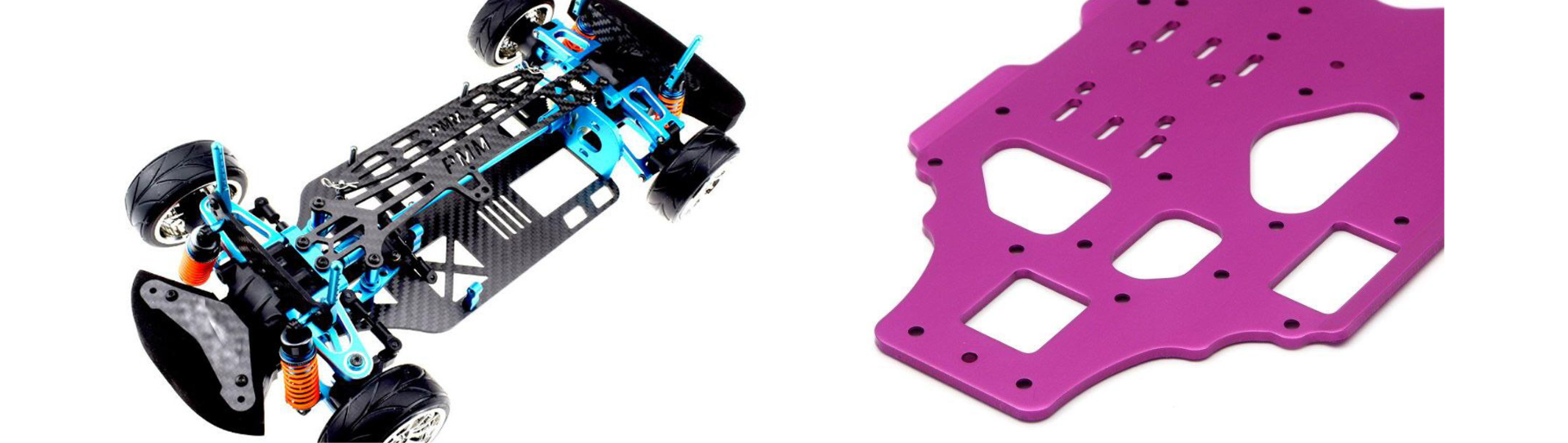

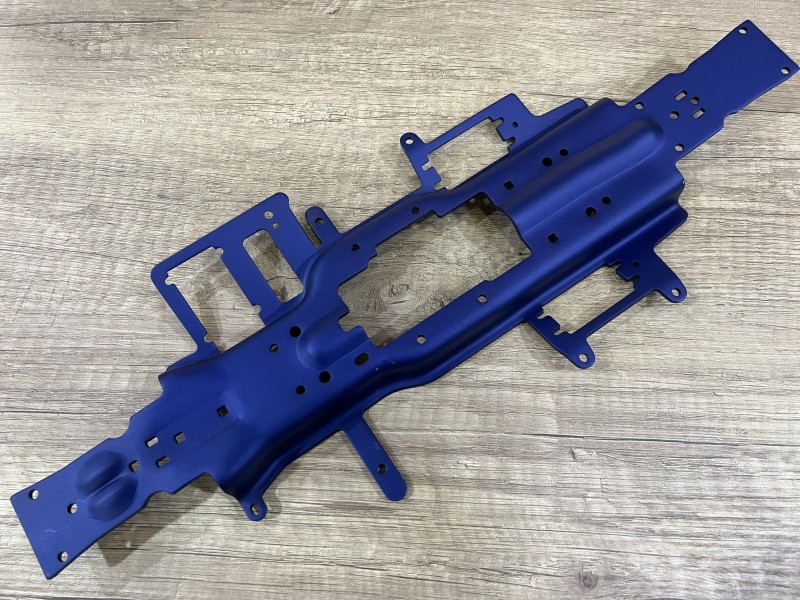

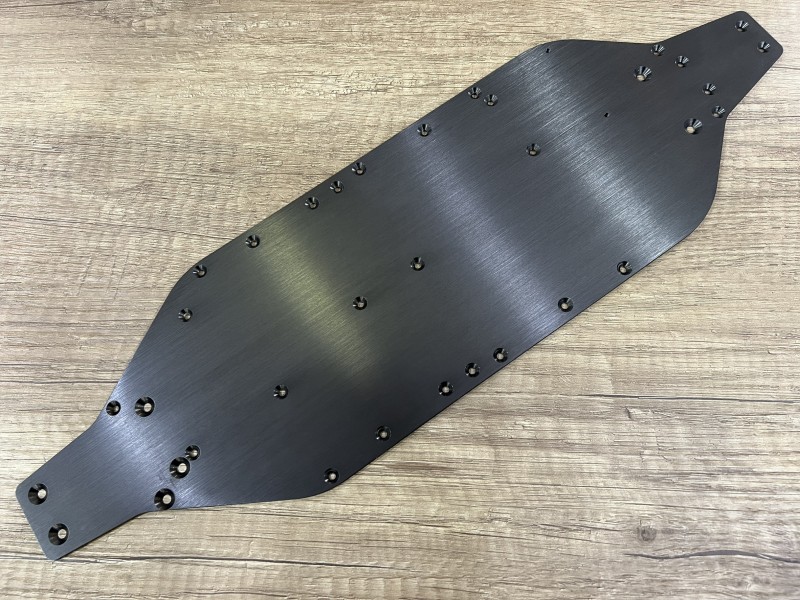

Materials and RC Applications

Common grades: stainless steel, aluminum alloys, low‑carbon steel, and corrosion‑resistant metals. Deep draw forming is applied to cups, covers, and cylindrical sub‑components; stamped brackets and flat parts complement chassis, suspension mounts, and linkage connectors.

Production and Lead Time

We handle small‑lot, multi‑variant runs as well as steady mass production. Capacity planning focuses on shared fixtures, integrated steps, and material yield to shorten lead time and stabilize unit cost. Share drawings, material spec, thickness, and quantities for a clear quote and schedule.

Inquiry

For RC parts using deep draw metal forming or combined stamping routes, send drawings and target quantities. Our team will return process notes, sample plans, and inspection checkpoints for project kickoff.